First, we need to understand the relevant information about aluminum nitride ceramics.

Aluminum nitride ceramics have high thermal conductivity and electrical insulation properties. They are an advanced ceramic material and are widely used in the electronics industry.

Aluminum nitride crystals belong to the hexagonal system. They are covalently bonded compounds with tetrahedrons as structural units and are wurtzite-type structures. At the same time, it is also a high-temperature resistant ceramic material. Its single crystal thermal conductivity is about 5 times that of alumina, and it can be used in an environment of 2200°C and has good thermal shock resistance.

At the same time, aluminum nitride is resistant to metal corrosion in a molten state and is almost not stable to acid. Because the surface of aluminum nitride is exposed to humid air, it will react to form an extremely thin oxide film. People use this property to use it as a crucible and casting mold material for smelting metals such as aluminum, copper, silver, and lead. Also because aluminum nitride ceramics have good metallization properties, they can replace toxic beryllium oxide ceramics and are widely used in the electronics industry.

Aluminum nitride ceramics The chemical formula of aluminum nitride is AlN, and the chemical composition of Al accounts for about 65.81% and N accounts for about 34.19%. Its powder is generally white or grayish white, and it is colorless and transparent in the single crystal state. The sublimation decomposition temperature under normal pressure reaches 2450℃.

The thermal conductivity of aluminum nitride ceramics is between 170~210 W/(m.k), and the single crystal can be as high as 275 W/(m.k) or more. High thermal conductivity (>170W/m·K), close to BeO and SiC; thermal expansion coefficient (4.5×10-6℃) matches Si (3.5~4×10-6℃) and GaAs (6×10-6℃); various electrical properties (dielectric constant, dielectric loss, volume resistivity, dielectric strength) are excellent; good mechanical properties, flexural strength is higher than Al2O3 and BeO ceramics, can be sintered at normal pressure; can be made by tape casting process.

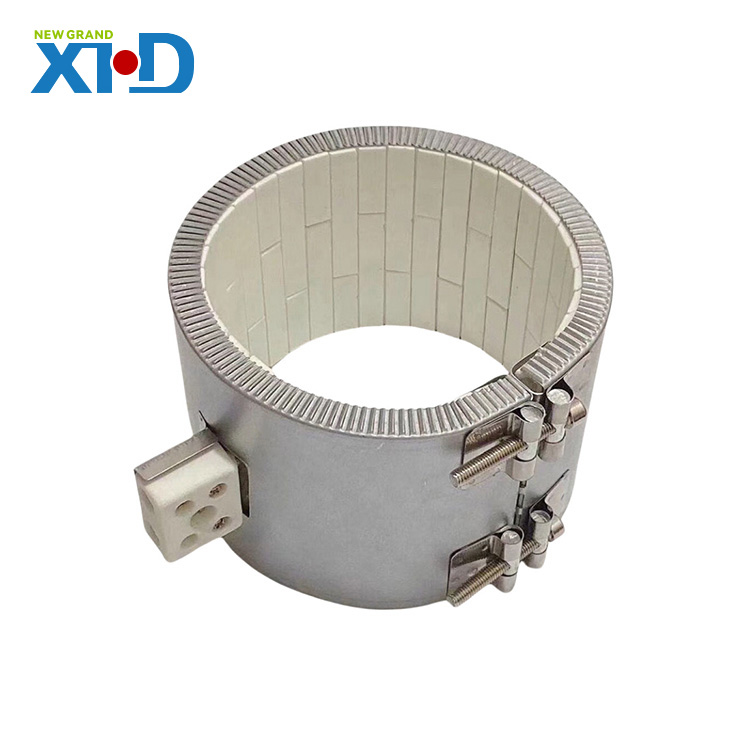

Aluminum nitride ceramics have high hardness and are brittle, so they are prone to edge collapse and cracking during processing. Usually, ceramic parts are processed using a dedicated ceramic engraving machine, which can effectively reduce costs and achieve high-precision processing. Xinhongda has developed a Ceramic Band Heater specifically for ceramic processing, which has good protection performance and high processing accuracy.

The Ceramic Band Heater enhances the rigidity of the machine tool, and the vibration generated during processing can be reduced to a minimum, which can ensure accuracy while improving processing efficiency. In addition, the protection performance is enhanced for ceramic powders, which can completely prevent powder damage to the machine tool. Xinhongda can also provide ceramic processing technology, with a skilled CNC processing and grinding team, precision parts research and development, and customized processing.